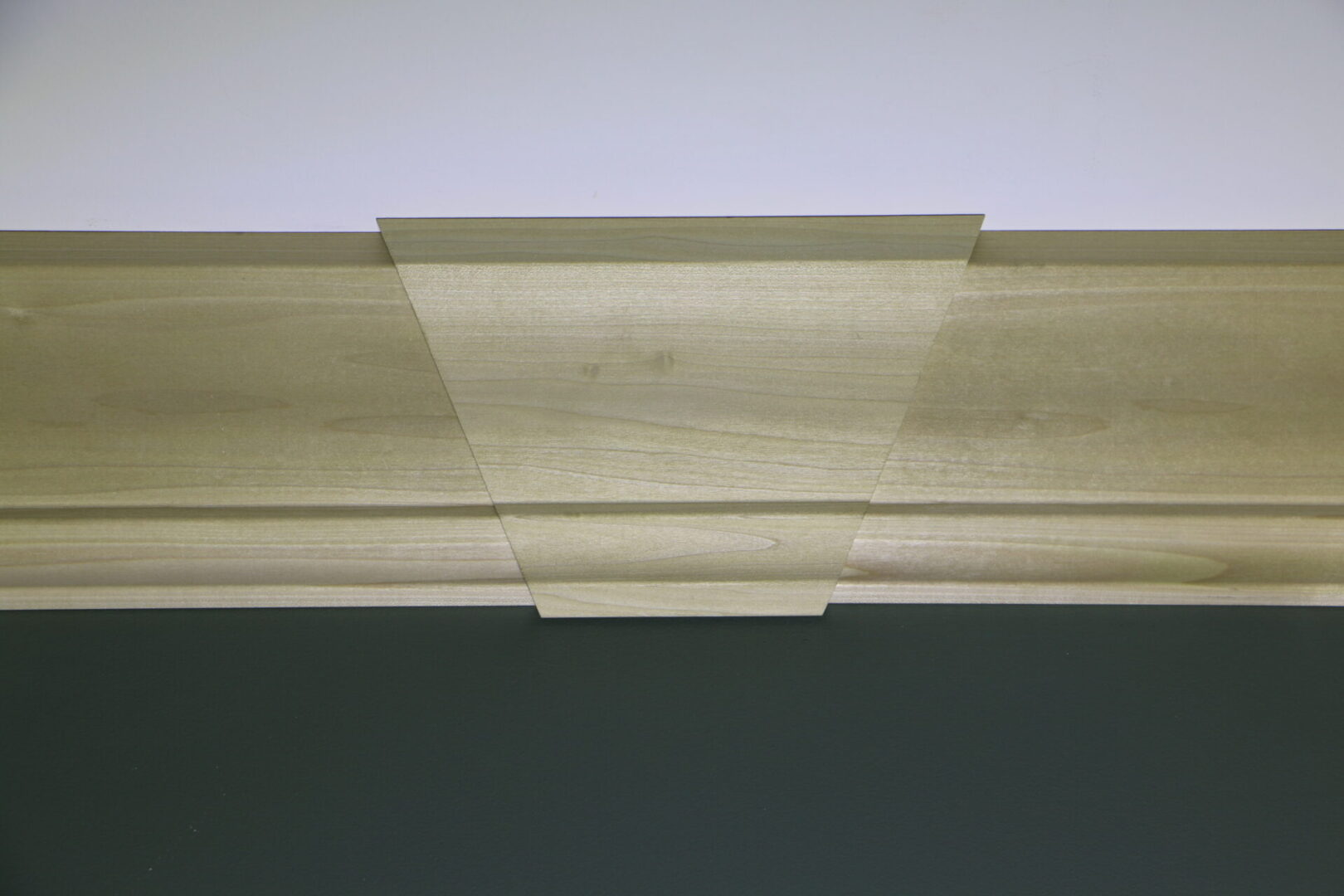

Removable Crown Moulding

Wire Management System

Paintable With Eco-Friendly

Water Based Paints

MDU and Hospitality

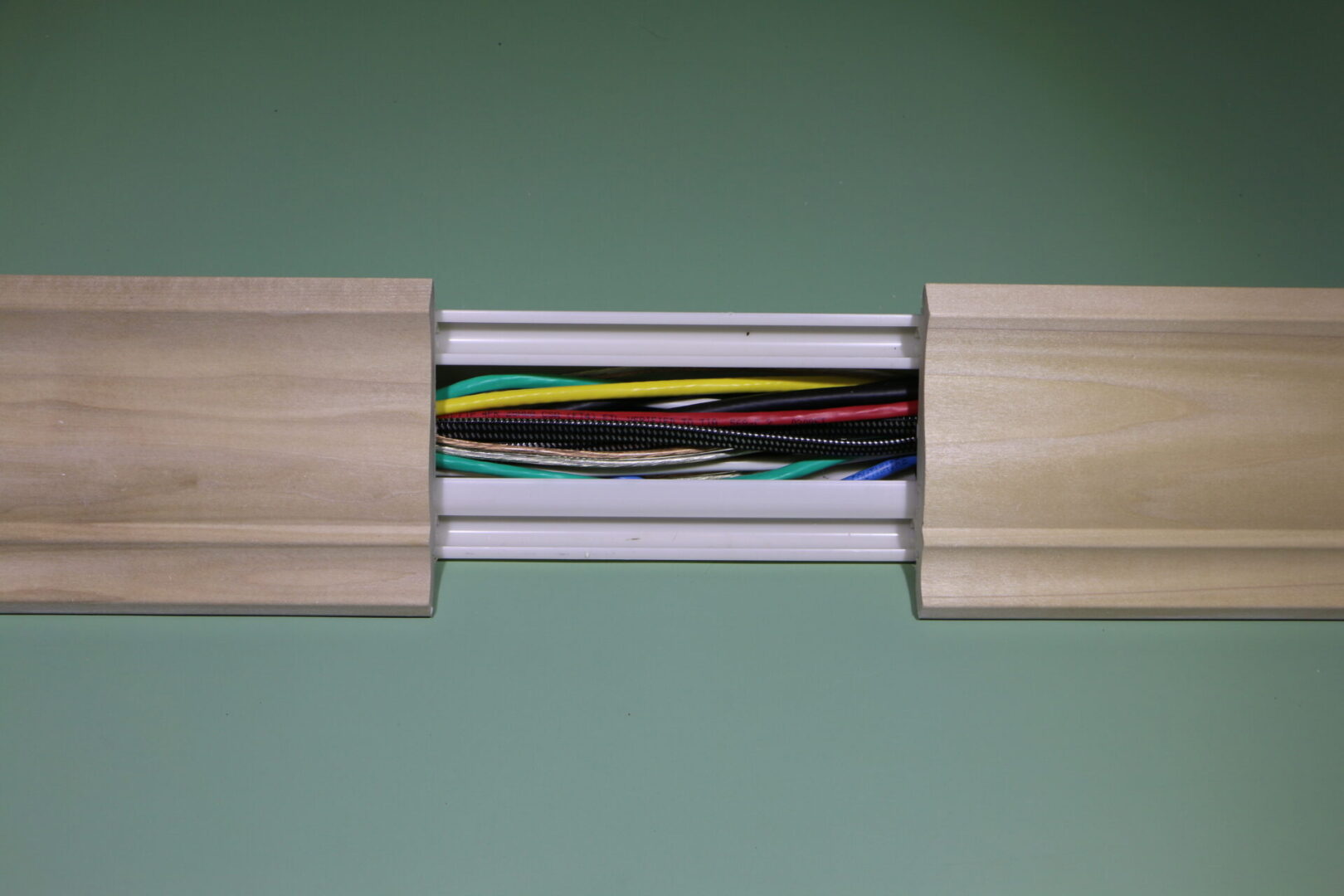

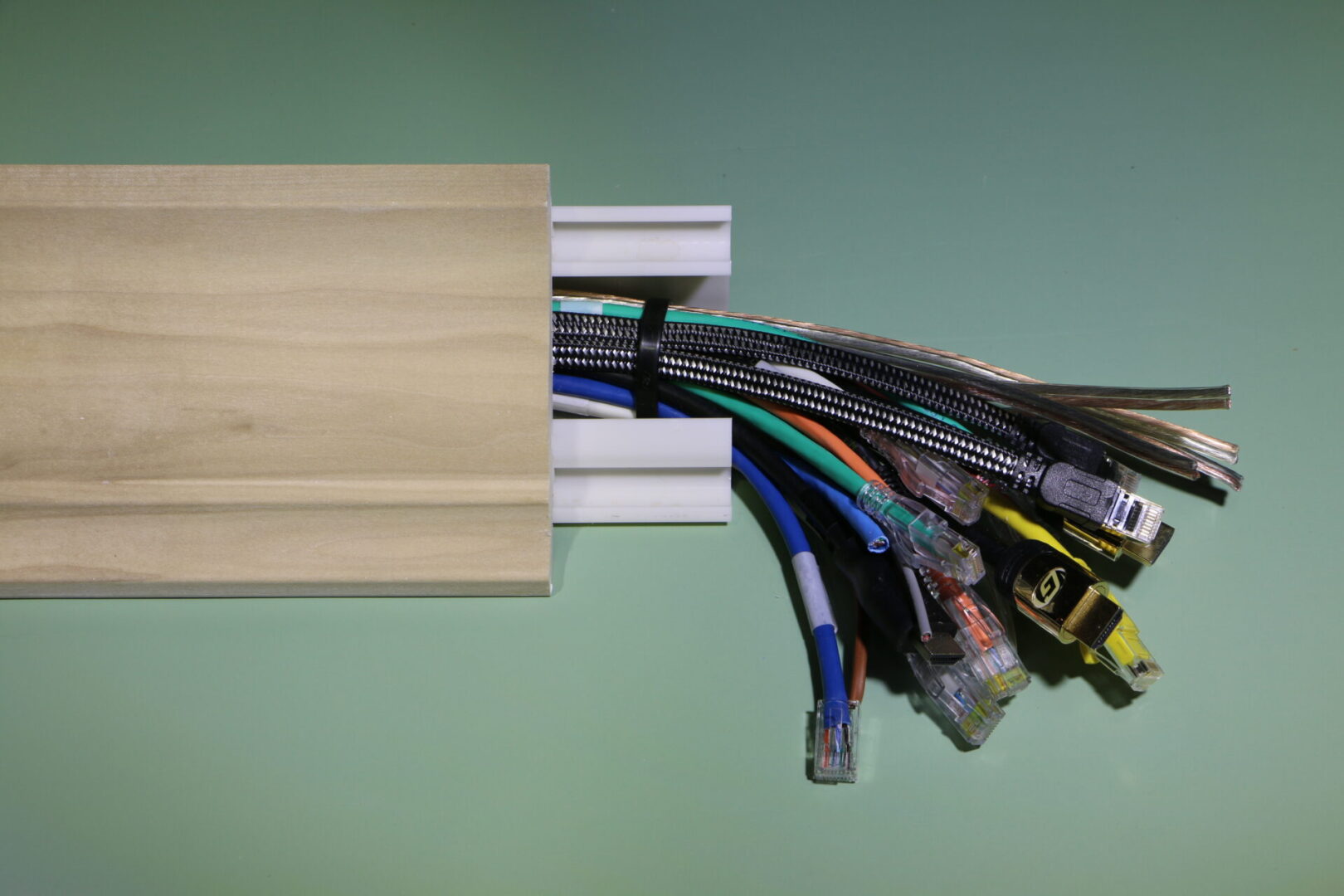

Crownduit is a locally sourced high performance removable nonmetallic wire management system used for telecommunication fit-outs that focuses on aesthetics and reduces the labor, materials and exposures involved with painting Ridgid PVC (uPVC) nonmetallic raceway systems on the market.

Crownduits poplar wood faceplate is FSC certified and is mechanically embedded into a RoHS, NSF compliant and UL94V.O listed uPVC clip. Poplar wood is non-toxic since it does not contain terpene hydrocarbons and does not emit toxic phenols. Crownduits poplar faceplate can easily be painted with latex paints, we recommend using eco-friendly water-based paints that meet the highest standards with Green Seal GS-11 certifications. To achieve ASTM E-84 Class A fire rating with zero smoke and zero flame spread, add 8 ozs of Flame Check M111PA Fire Retardant additive per gallon of paint. Flame Check M111PA fire retardant additive is natural, non-toxic, non-corrosive, non-allergic and environmentally safe for use in areas with daily human contact.

Available at Crownduit.com for MDU and Hospitality in 9'10" Lengths

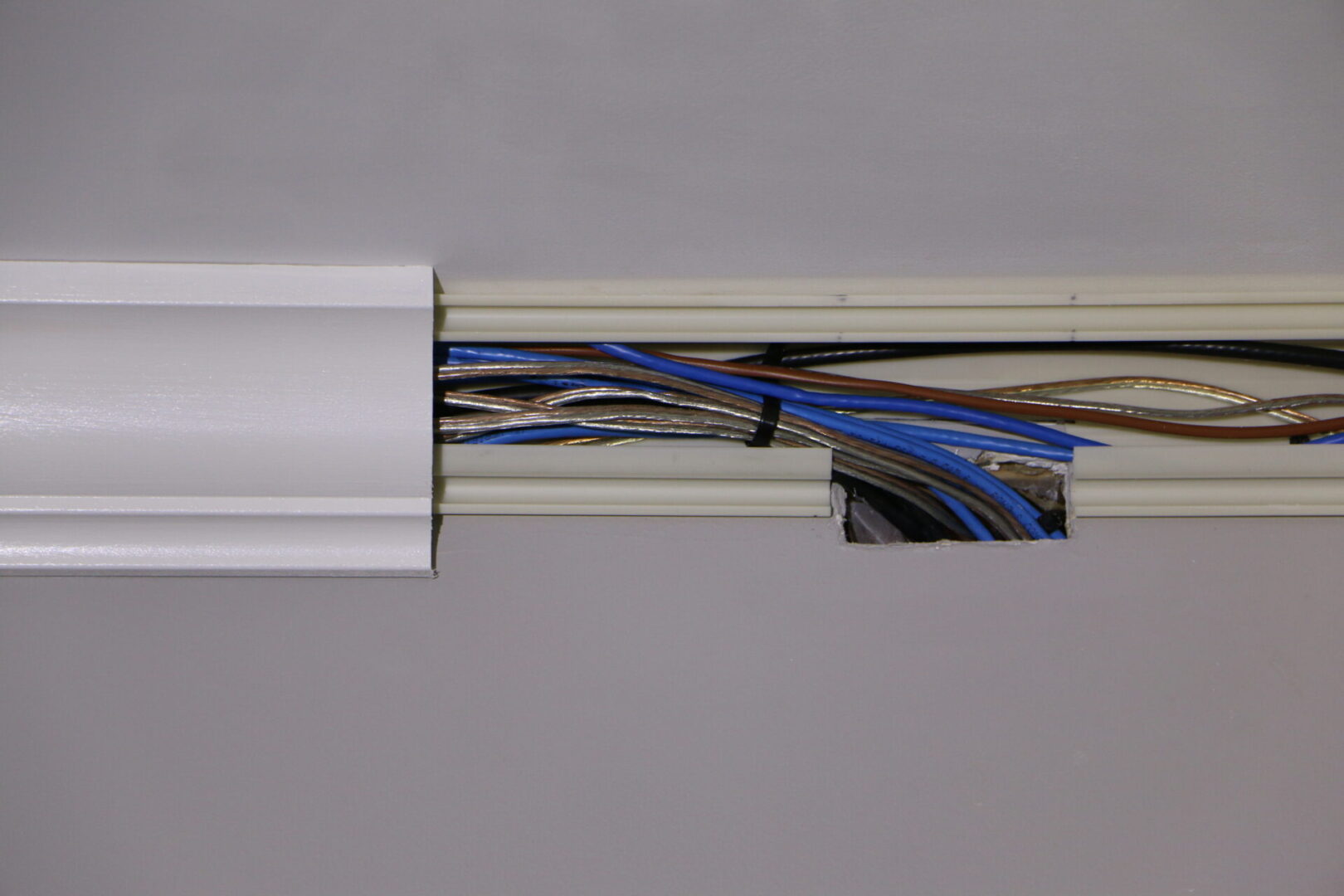

Painting Non-Metallic Rigid PVC Wire Management Systems with Exposed uPVC Faceplates

Uncontaminated uPVC can be recycled up to 15 times. Paint coating on uPVC will significantly limit the quality, lifespan and its ability to be recycled. Manufacturers are reluctant to accept painted uPVC for regrind since paint flecs can contaminate the flow and clog the screen packs in the extrusion tooling.

Latex is a term commonly used to describe a dispersion or emulsion of a polymer in water. The presence of the paint polymers on the uPVC can contaminate the uPVC recycling stream. Painted uPVC will most likely be deposited in a landfill.

Recently installed uPVC should not be painted for at least 12 months due to the resins and internal mold release agents used during the extrusion process slowly migrating to the surface, which can cause paint adhesion failures. You will notice that the uPVC surface will appear less shiny and conseqently less hydrophobic after a year has passed. This helps with paint adhere to what would be an incredibly difficult surface to bond to.

If you do paint new uPVC, paintability might not be impaired immediately. Adhesion tests might show excellent adhesion since the surface was initially prepared for paint, with paint adhesion failure occuring long after the part was put into service, especially during removal for service access.

Ridgid PVC was not designed to be painted. Waterbased Latex paints lack the solvents to etch the surface to improve adhesion. Sanding the surface to create a mechanical grab and an acetone wipe to swell the surface to make it more porous and remove waxes used during manufacturing will help with paint adhesion.

The strength and stiffness of the paint are different than the plastic, but they have to move togeather as a unit during removal.

Premium plastic bonding primers can be top coated with almost any kind of coating, acrylic, latex, urethane and are designed for surfaces that expand and contract. uPVC paints have under gone extensive testing and rigorous assesments and have achieved ISO(International Organization for Standardization) ratings guaranteeing their bonding and durability. uPVC paints are especially formulated to act as a chemical bridge between the plastic and the paint, therefore they can be applied to various types of PVC, polycarbonate, acrylic, polyester and uPVC. Plastic flexible paints or paint flex additives are recommended to be used for plastic that needs to be flexed, bent or twisted. uPVC attracts dust to its surface more that most building materials, anti-static paint additives should be included.

Take precautions when sanding uPVC to create a mechanical paint bond. Cutting or sanding uPVC causes friction that will cause heat, which can release toxic chemicals in the dust (hydrogen and chloride). Acetone has a half life of 22 days and its tiny molecules can pass right through HEPA filters. Wood dust: although severe reactions are quite uncommon, see articles "Wood Allergies and Toxicity" and "Wood Dust Safety" for more information.

Smart Home Automation Future Proof Your Home

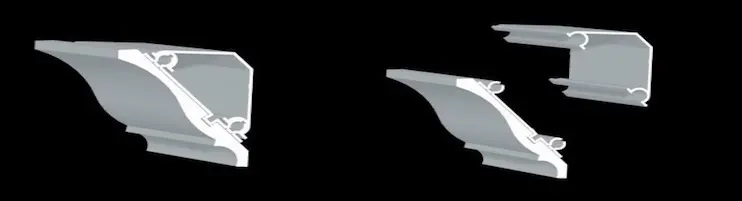

Crownduit® is a patented wood crown moulding system that is service accessible and serves as an aesthetically pleasing way to route, conceal, upgrade and protect HDMI, speaker wire, ethernet, POE devices, alarm and security cameras, audio/video, home theater, motorized shades, video doorbells, intelligent lighting and wireless access points.

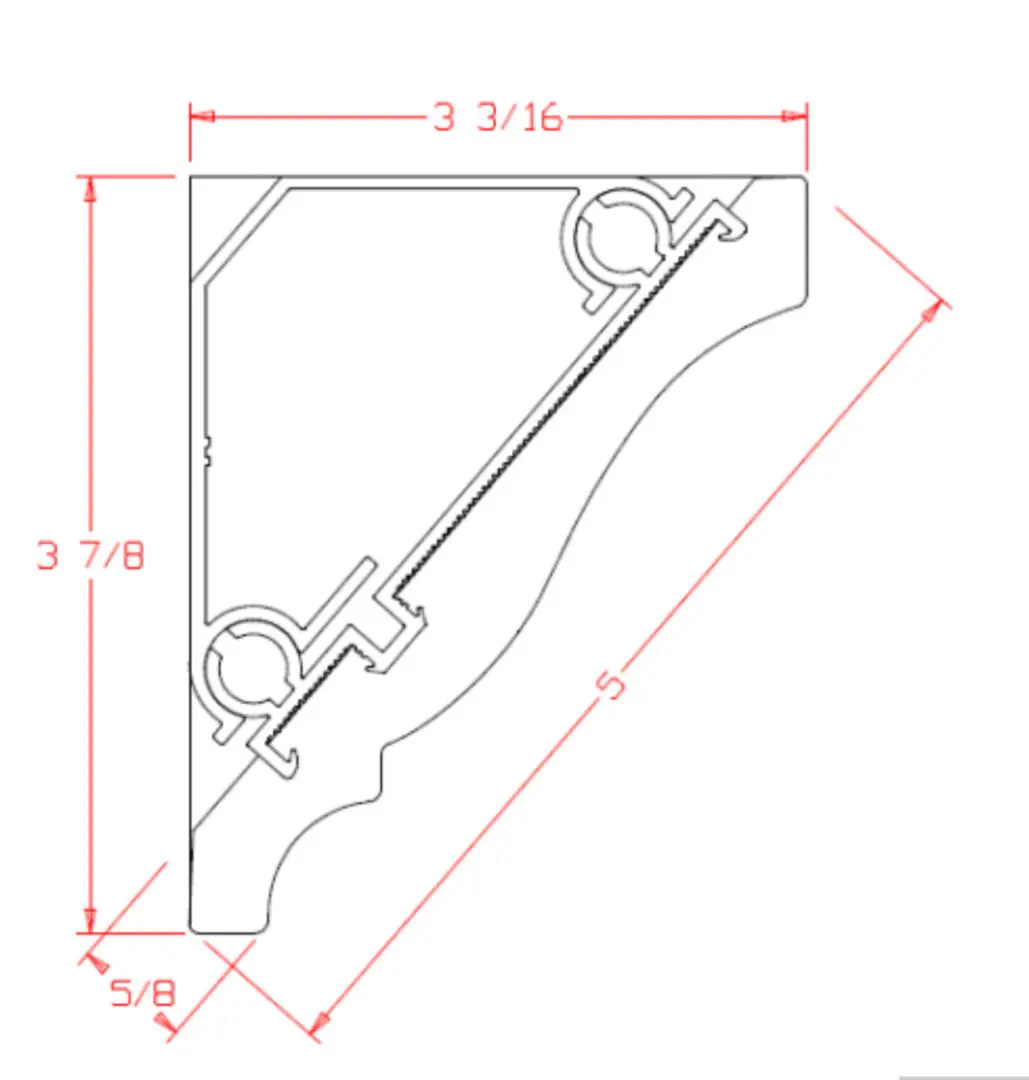

The Crownduit System ships with 4 lengths of moulding and 4 lengths of backtrack in each carton at 7'10" lengths. Two lengths of moulding at 7'10" each with two inside corners and one keystone will cover a 16' wall.

Available at Crutchfield.com for the Homeowner

DIY Installation

Crownduit can be pre-finished to desired color prior to installation, installs blemish free without nails, glue or putty. Straight cuts with no mitering required, install track and snap on finished crown.

Product Overview